Turnkey Automation Solution for the Sawmill Säge Paskov s.r.o

Mayr-Melnhof

Säge Paskov s.r.c. (Northern Morovia, Czech Republic) is one of the largest and highly modern sawmills of the Mayr-Melnhof group.

As a long-term partner of Mayr-Melnhof, Sprecher Automation was assigned to deliver a turnkey solution consisting of power supply, control and scanner systems.

By building a new sawmill beside Leoben, Mayr-Melnhof has particularly prepared for the overseas markets such as USA and Japan.

In May 2003, Sprecher Automation received the orders for the complete power supply and distribution as well as the complete electronic equipment for one log yard, for the twin saw infeed and the cutting pattern-based log rotation at the new sawmill in Paskov.

Automation, scanner systems and power supply

Product and service range

- Planning and project management

- 10 kV SPREPOWER medium voltage switchgear

- 0.4 kV SPREPOWER low voltage switchgear

- SPRECON-E control and protection systems

- Main supply connection to the pulp mill of Biocel

- Overall cabeling

- Production data acquisition for fault alarms and for sustaining service intervals

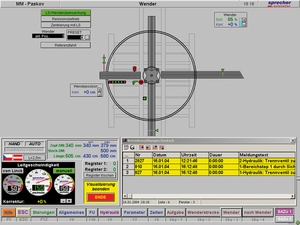

- Electronic control sytems for the log yard including plant visualisation

- Conveying technology including frequency converters for the log yard

- SPRESCAN 2D-512 dimension scanner

- SPRESCAN 3D main scanner for log acceptance

Power supply and distribution

The power supply and distribution project contained infeed, medium and low voltage distribution including planning, project management and cabling works. Power is supplied through busbars with nominal currents up to 3,000 A. Furthermore, 12-bay compensation stations were integrated into the power system.

The adjacent pulp mill of Biocel supplies the Mayr-Melnhof Säge Paskov s.r.o by feeding 5 MVA into Sprecher‘s 11-bay 10 kV SPREPOWER medium voltage switchgear via 2 lines. The switchgear is operated by SPRECON-E control devices for energy stations.

The power system is controlled by change-over switching, which is coupled with frequency-dependent load shedding.

Each infeed line can therefore take over the load of the other line in case of a fault.

Sawmill technology

For the log yard, Sprecher Automation provided the overall control systems and plant visualisation as well as conveying technology including frequency converters. Furthermore, Sprecher‘s world-wide approved SPRESCAN scanners were installed there.

SPRESCAN 2D-512 measures log dimensions before debarking and separation.

SPRESCAN 3D acts as the main measuring system for log acceptance. The scanner also calculates sorting criteria. All incoming logs are measured and evaluated with the SPRESCAN scanner systems. Furthermore, they are sorted by wood type, diameter, length and quality at a range of 85 different product categories. All production data directly flow into the central database of the Mayr-Melnhof group.

The Paskov sawmill acts as a „closed circle“: Bark is burned which leads to heat used for drying. Sawings are shipped to secondary industries and chips to paper industries. Both materials are separated directly at the machine by sieving.

Full operation of the sawmill was achieved within three steps. In 2006, the planned annual production capacity of 1 million solid meters could be finally met.