Process automation for an entire facility

RAPSO Austria GmbH

Founded in 1989 and headquartered in Aschach an der Donau, Rapso is Austria‘s most successful rapeseed oil producer in the cooking oil market.

Sprecher Automation was commissioned to renew the process automation for the entire electrical engineering system. The modernisation concerned the low voltage distribution board, the motor control, the control system, the visualisation and the electrotechnical installation.

High time for increased operational safety & efficiency

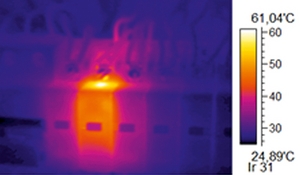

The previous automation system and the electrical engineering technology dated back to when the plant was first set up in 1991. As a result, the life cycle of the system had already been significantly exceeded and the original premises had no space in reserve for extensions. As a result of the aging process and the aggressive environmental conditions, there was also an increased risk of larger numbers of operational disruptions, as well the risk of fire.

The sustainable modernisation concept

As a major project requirement, a new e-room was set up both to accommodate the current plant components and to guarantee space for future expansion. The low voltage main distribution boards (including reactive power compensation equipment, motor control cabinets, PLC, UPS and emergency lighting systems as well as the computers) could now be set up in this room and prewired in parallel to ongoing operations.

Perfect environmental conditions

The new air conditioning technology in the 72 m² e-room ensures both the operational safety and longevity of the equipment, as well as pleasant conditions in the control center room and in the social area.

From the analog period to the digital age

The automation system for the control center is now as modern as they come: it is operated via a control center with two workstations offering an overall display of the system on an 84inch monitor. The new technical possibilities mean that lots of processes can be automated, thereby relieving the burden on employees. Remote access was installed to facilitate the maintenance and servicing of the entire automation system.

Project facts

-

1,500 digital in- and outputs

-

200 analog in- and outputs

-

Redundant servers with loop structure and control system

-

132 drives (32 of them with frequency converter)

-

37 control cubicles

-

122 local control stations

-

Approx. 1,200 cables have been installed (with an overall cable length of about 50,000 lm)

Hygienic – durable – clear

The cables for every drive, load and sensor own very good resistance to chemicals and are impervious to vegetable oils and fats. The project also included the dismantling and rebuilding of the main stainless steel cable routes as well as all of the rewiring work.

Furthermore, the fire alarm system in the oil mill building and the associated outdoor area, along with the entire lighting and socket installation, were replaced, recased and rewired and a batterypowered emergency lighting system was installed.

Commissioning – when speed is essential

The new electrical system and the installation works were implemented in parallel to ongoing operations in the first half of the year. During the annual six week production break in summer, the actual remodelling and commissioning took place. Immediately after the end of the maintenance shutdown, full operation was resumed to the complete satisfaction of the customer.